Acrylic Mirror vs Polycarbonate Mirror

M acrylic sheet, Polycarbonate takardar, PS takardar, PETG takardar kama sosai kama, a cikin launi iri ɗaya, kauri iri ɗaya, yana da wahala ga waɗanda ba ƙwararru ba su bambanta tsakanin su.A cikin labarin da ya gabata, mun gabatar da bambanci tsakanin acrylic da PETG , a yau muna ci gaba da bayani game da madubi acrylic da madubi na Polycarbonate a gare ku.

| Acrylic | Polycarbonate(PC) | |

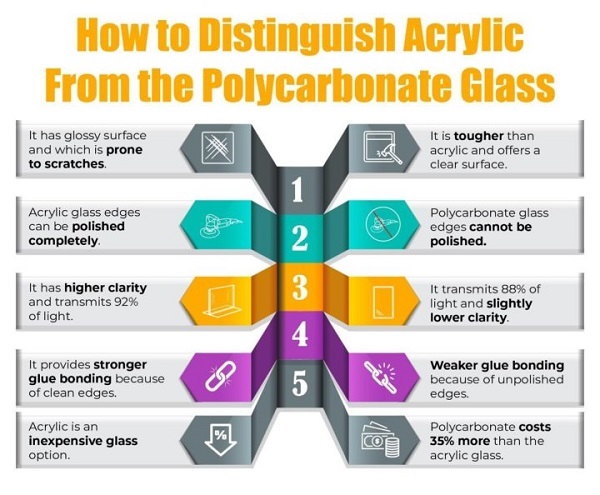

| Rganewa | Acrylic yana da saman gilashi kamar mai sheki kuma yana goge saman da sauƙi.Ya fi bayyane kuma ana iya yin laushi don samar da kowane nau'i. Acrylic yana da cikakkun gefuna masu haske na gilashi waɗanda za'a iya goge su gaba ɗaya.

Idan ya ƙone shi da wuta, harshen wuta na acrylic yana bayyana lokacin konewa, babu hayaki, babu kumfa, babu sautin ƙararrawa, babu siliki lokacin kashe wuta.

| Idan saman yana da tauri, barga, bayyananne, kuma ya fi nauyi fiye da zanen acrylic, polycarbonate ne. Ba za a iya goge gefuna na takardar polycarbonate ba.

Ƙonawa da wuta, polycarbonate ba zai iya ƙonewa ba, mai saurin wuta, kuma zai fitar da wani hayaki mai baƙar fata. |

| Tsaratarwa | Acrylic yana da mafi kyawun haske tare da watsa haske 92%. | Polycarbonate ɗan ƙaramin ƙarancin tsabta tare da watsa haske 88%. |

| Ƙarfi | Kasancewa kusan sau 17 mafi tasiri fiye da gilashi | Polycarbonate yana fitowa a saman.Mahimmanci mai ƙarfi, tare da 250 sau fiye da juriya mai tasiri fiye da gilashin da ƙarfin tasiri na 30 fiye da acrylic. |

| Dorewa | Dukansu suna da tsayin daka.Amma acrylic yana da ɗan tsauri fiye da polycarbonate a zafin jiki, don haka yana yiwuwa ya guntu ko fashe lokacin da aka buga shi da wani abu mai kaifi ko nauyi.Duk da haka, acrylic yana da taurin fensir mafi girma fiye da polycarbonate, kuma ya fi tsayayya ga karce. | Sakamakon fasali na musamman kamar ƙaramin matakin flammability, karko, ana iya hako polycarbonate ba tare da fashe guntuwa ba. |

| Batutuwan samarwa | Ana iya goge acrylic idan akwai ƙaramin ajizanci.Acrylic ya fi tsayi, don haka yana buƙatar zafi don samar da shi zuwa siffofi daban-daban.Duk da haka, zafi baya lalata ko rushe kayan kwata-kwata, don haka babban zaɓi ne don thermoforming. Acrylic kuma za a iya kafa ba tare da pre-bushe tsari, wanda ake bukata a polycarbonate forming. | Polycarbonate ba zai iya gogewa ba don dawo da tsabta.Polycarbonate yana kula da zama mai sauƙi a cikin zafin jiki, wanda shine ɗayan halayen da ke sa ya yi tasiri sosai.don haka ana iya siffata shi ba tare da an yi amfani da ƙarin zafi ba (tsari da ake kira sanyi forming).An san shi don kasancewa mai sauƙi don na'ura da yanke. |

| Aikace-aikace | An fi son acrylic a lokuta inda ake buƙatar abu mai haske da nauyi.Hakanan yana iya zama mafi kyawun zaɓi a cikin lokuttan da ake buƙatar takamaiman girma da siffa, tunda yana da sauƙin ƙirƙirar ba tare da tasiri ga ganuwa ba.Acrylic sheeting ya shahara a cikin waɗannan aikace-aikacen: · Abubuwan nunin dillali · Fitilar hasken wuta da faifai masu yaduwa Ɗalibai na bayyane da masu riƙe don ƙasidu ko kayan bugawa · Alamun ciki da waje · Sana'ar ayyukan DIY · Fitilar sama ko tagogi na waje waɗanda ke fuskantar matsanancin hasken UV

| An fi son polycarbonate sau da yawa a lokuttan da ake buƙatar ƙarfin ƙarfi, ko kuma a lokutan da kayan za a iya fallasa su zuwa zafi mai zafi (ko juriya na harshen wuta), tun da acrylic na iya zama mai sauƙi a cikin wannan yanayin.Musamman ma, polycarbonate sheeting yana shahara a cikin waɗannan lokuta: · tagogi da kofofin “gilashin” masu jure harsashi · Kariyar garkuwar iska da ma'aikata a cikin motoci daban-daban · Tsare-tsare masu gani a cikin kayan wasan kariya · Abubuwan fasaha · Masu gadin injina · Masu gadi a wuraren masana'antu inda zafi ko sinadarai suke Makin UV don sigina da amfani na waje

|

| Farashin | Filastik acrylic ba shi da tsada, mafi araha fiye da filastik Polycarbonate.Farashin acrylic ya dogara da kauri daga cikin kayan. | Polycarbonate yana da farashi mafi girma, kamar 35% mafi tsada (dangane da sa). |

Da fatan za a bi kafofin watsa labarun mu da gidan yanar gizon mu don ƙarin koyo game da bambancin sauran robobi.

Lokacin aikawa: Yuli-25-2022